CUSTOMERMotor Manufa cturer Midwest United States

|

|

|

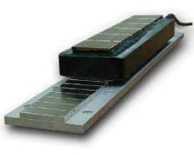

APPLICATION Stator enc apsulation.

CHALLENGE The company manufa ctures a wide range of linear, servo and permanent magnet motors, including models used in dirty duty, spark resistant and washdown applic ations. Motor windings need to be enc apsulated to protect copper windings and prevent electric al shorts. Enc apsulants also need to be used around motor leads to prevent air and moisture from getting into the windings.

Motor windings are densely configured with little room for resin saturation. The challenge was to provide a heated meter/ mix system c apable of maintaining an elevated resin temperature such that when it was introduced into the motor windings, the lowered viscosity would provide thorough penetration in and around the coil interstices.

In preliminary tests conducted at Exa ct’s fa cilities, it was determined that a va cuum environment would be required to ensure thorough enc apsulation of the windings. Motors were pre-heated to further fa cilitate saturation.

|

|